Harden® Single Shaft Shredder SG Series

Harden® has rich experiences in single shaft shredder, for Shredding RDF, Fabric, Leather, Paper Mill Waste, Plastic, Wood.

Model:SG & SL Series

Harden® has rich experiences in single shaft shredder, for Shredding RDF, Fabric, Leather, Paper Mill Waste, Plastic, Wood.

Model:SG & SL Series

132 / 200 KW Optional

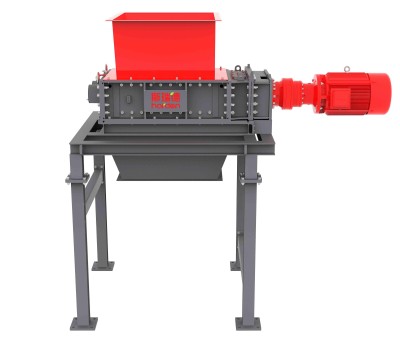

for Shredding Metal Scrap, Rager Wires, and other tough materials.

Model:TDH912 & TDH1216

45x2 / 75x2 / 132x2 KW Optional

for Shreddding Medical Waste ,Hazardous Waste, Municipal Waste

Model:TD1216

Shreddding Drums,Hazardous Waste, Bulky Waste, Household Appliances

Model:QS1012

160/200/250/160*2 KW PQ Control Optional

Shredding MSW Biomass Waste RDF Production, etc.

Model:TPH1620

Harden® Two Shaft Shredder are economical, produced with well workmanship. for Shredding Organic Waste, E-Waste, Plastic, Wood

Model:TS612

for Shredding Medical Waste, Electronic Waste, etc

Model:TS508

7.5KW

for Shredding Medical Waste, Electronic Waste, etc

Model:TS303

According to the principle of mechanical vibration, a single drive is used to generate dual vibrations, so the dynamic screen plate obtains extremely high acceleration through tension and relaxation deformation.

lt is suitable for difficult-to-screen materialsespecially materials with high wet viscosity that are prone to clogging and jamming. The flexible screen plate and relaxation efficiency have powerful screening and anti-blocking performance.

Model:SZS-F1652

The step vibrating screen is based on the principle of mechanical vibration.

The exciter provides the excitation force to drive thescreen plate to vibrate in a circle.

The materials are stratified and transported under the vibrating projection of the screen machine.Materials smaller than the mesh size fall down and are transported, which is complete particle size classification.

Model:SZS-S2060

The composite vibrating screen organically combines the two single screening technologies of the stepped circular vibrating screen and the relaxation screen into one, so that one device can achieve two screening effects at the same time.

Based on the principle of mechanical vibration, this equipment uses a single excitation source to provide excitation force and simultaneously drives the upper and lower sieve plates to produce different forms of vibration. The upper sieve plate is a circular vibration, and the lower sieve plate is a relaxation motion. The material moves in the screen machine Under the action of vibration projection, stratification and transportation are realized, and materials smaller than the mesh size fall down and complete the particle size classification.

Model:SZS-C1660

HARDEN triangular roller screen is an innovative screening equipment developed with multiple patented technologies to meet the diverse needs of solid waste treatment processes. It features a unique design that allows for modular combination and assembly, catering to various screening size requirements while prioritizing innovation, energy efficiency, and environmental sustainability. With its low energy consumption, minimal noise, high efficiency, and exceptional screening pass rate, this equipment represents a significant advancement in screening technology.

Model:TDS2000/TDS3000/TDS5000

HARDEN disc screen is a screening equipment that rolls and separates materials of different sizes and shapes through polygonal discs. All the polygonal discs rotate in the same direction with the rollers, causing the materials on the polygonal discs to achieve a compound movement of horizontality and tumbling, making the materials looser.

The materials are hit, spread, and perform jumping and tumbling motions by the rotating polygonal discs. During the process, the particle size smaller than the gap between the discs will be missed from the gaps on the side of the polygonal disc, thereby realizing the screening function.

Model:SDS1630/SDS1650

Handle a wide variety of materials while incurring low maintenance costs.

Model:SFX800/SFX1200/SFX1400