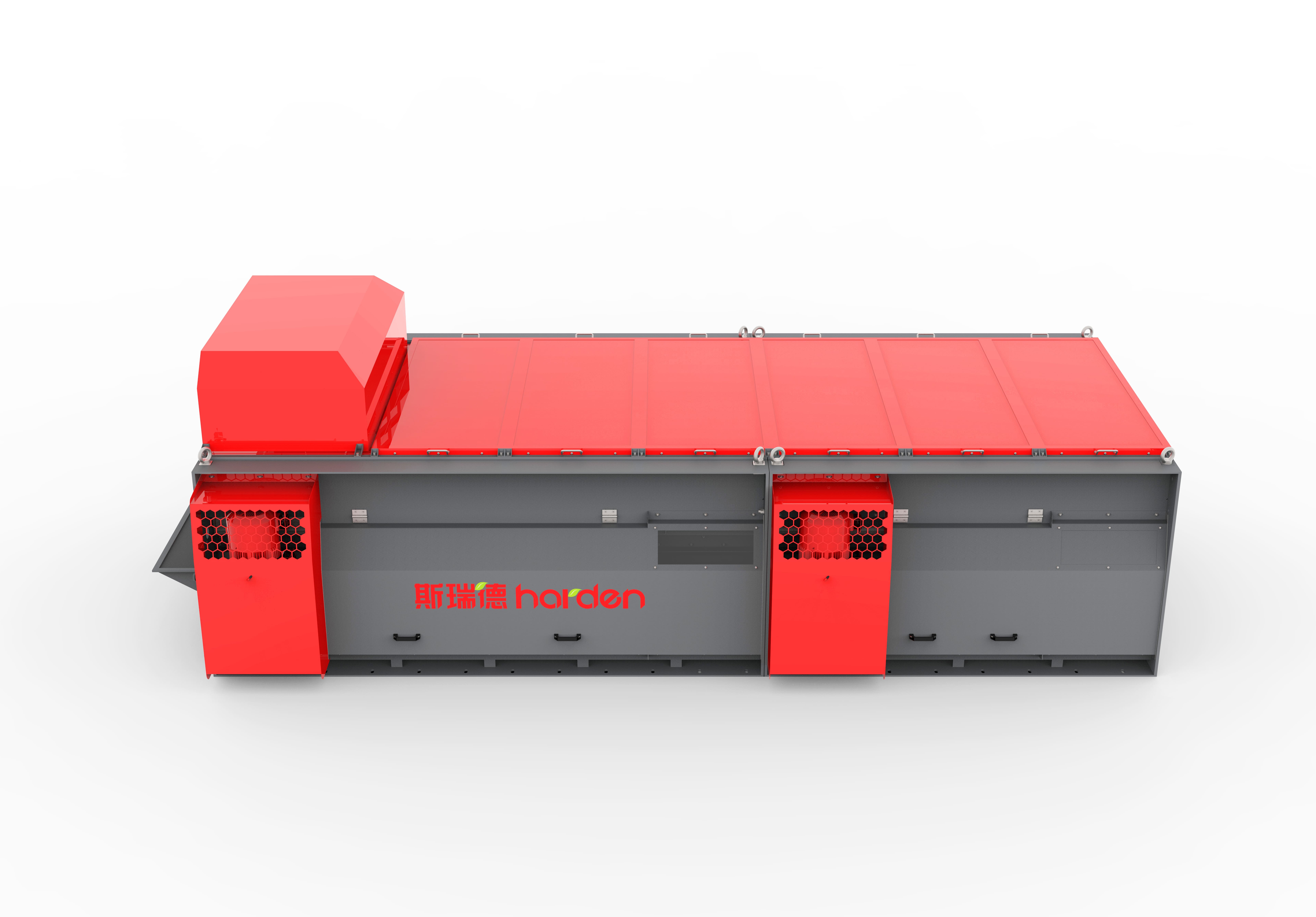

Disc Screen

- Model

- SDS1630/SDS1650

Review

Description

Disc Screen

HARDEN disc screen is a screening equipment that rolls and separates materials of different sizes and shapes through polygonal discs. All the polygonal discs rotate in the same direction with the rollers, causing the materials on the polygonal discs to achieve a compound movement of horizontality and tumbling, making the materials looser.

The materials are hit, spread, and perform jumping and tumbling motions by the rotating polygonal discs. During the process, the particle size smaller than the gap between the discs will be missed from the gaps on the side of the polygonal disc, thereby realizing the screening function.

Product Parameter

|

Model

|

SDS 1630

|

SDS 1650

|

|

Power(KW)

|

7.5

|

7.5*2

|

|

Motor quantity (set)

|

1

|

2

|

|

Working side size(L*W)

|

3*1.6m

|

5*1.6m

|

Capacity(T/H) | 15-20 | 18-20 |

Screen hole size(mm) | 20-350 | 20-350 |

Electricity Control | Frequency conversion | Frequency conversion |

Machine Weight(KG) | ~3500 | ~5500 |

The processing capacity is calculated based on the MSW density of 350kg/m³ and the sieve size of 80mm. | ||

Advantages At A Glance

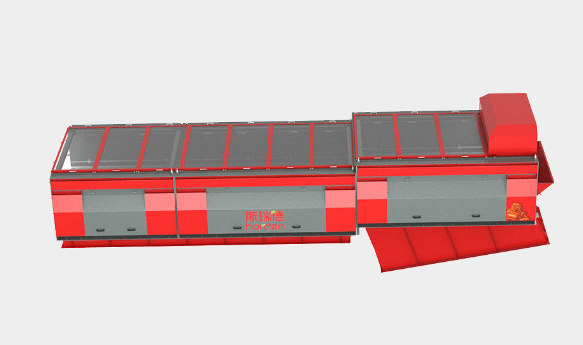

Modular design

Unit module design, easy transportation, and installation; large processing capacity, open screen surface, easy maintenance

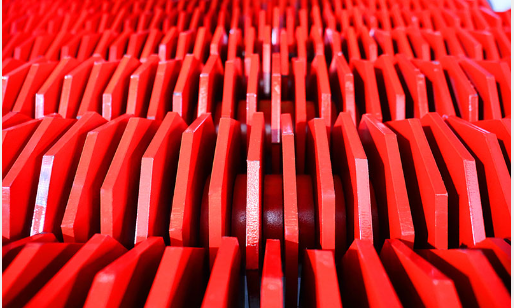

Hexagonal or octagonal curved disc design

Selected module quantities, easy maintenance

Adjustable screen hole

10-200mm

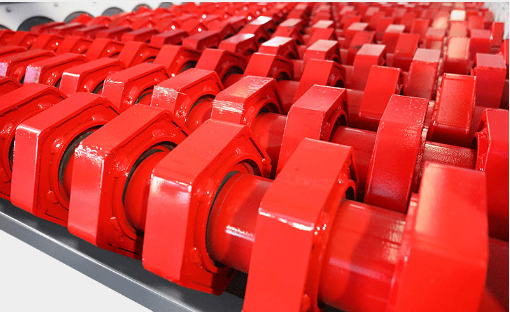

Patented multi-layer sleeve design to prevent material jamming

For large screen holes, a patented anti-winding design is added, which can effectively prevent hard materials from jamming the machine or flexible long materials from being entangled

Frequency conversion infinite speed control

Low energy consumption, high safety performance, adjustable processing capacity

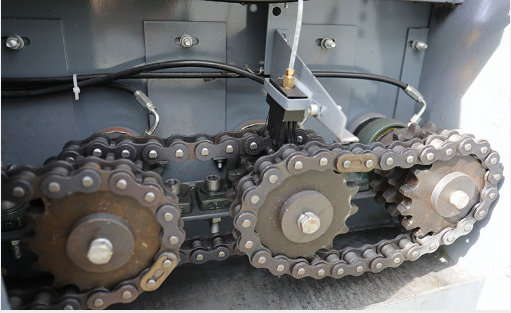

Wear-resistant chain linkage

More stable operation

Typical Application Range

Industrial Waste

Construction Waste

MSW

Landfill Mining

Organic Waste