Wind Shifter

- Model

- SFX800/SFX1200/SFX1400

Review

Description

Product Introduction

Wind Shifter

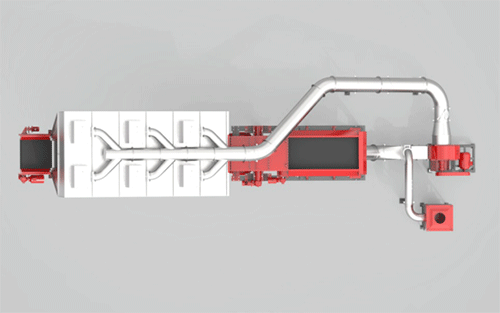

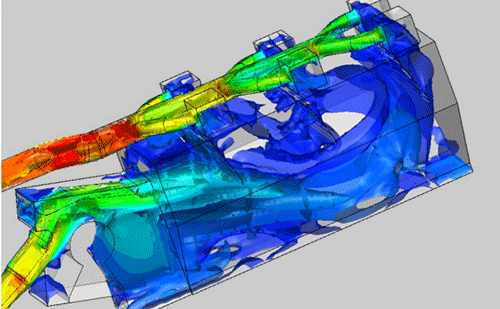

The blast wind shifter consists of a circulation extension unit, a separation drum unit, a conveyor, a diffusion chamber, and a dust collector. Operating on the principles of aerodynamics, this equipment employs controllable airflow as the medium for sorting. With the aid of controllable airflow, materials are separated based on density and particle size. The airflow can carry lighter materials upwards or horizontally to a distant location, while heavier materials either fall due to lack of support from the updraft or are propelled closer horizontally due to inertia. This wind sorting process leverages the settling characteristics of various solid wastes in the air to achieve the objective of classification, recycling, and reuse.

Product Parameter

Technical Parameters | |||

|

Model

|

SFX800

|

SFX1200

|

SFX1400

|

Feeding Material Width | 800 | 1200 | 1400 |

|

Processing Capacity

|

60m³/h

|

120m³/h

|

145m³/h

|

|

Installed Power

|

33KW

|

42KW

|

58KW

|

|

Machine Size

|

13600X3600X6000mm

|

17600X5200X6900mm

|

20000X6500X8100mm

|

Voltage | AC380V/50Hz | ||

Product Features

Efficient recirculation airflow technology, high efficiency, and low energy consumption

Modular design, easy assembly, and modules can be quickly adjusted

The system has high reliability, and strong adaptability, and can handle a variety of materials with low maintenance costs

The entire system adopts negative pressure technology to reduce dust emissions

Typical Application Range

Construction Waste

Biomass Waste

Industrial Waste

MSW

Electronic Scrap

Waste Plastic

Stale Waste

Incineration Residue