Composite Screen

- Model

- SZS-C1660

Review

Description

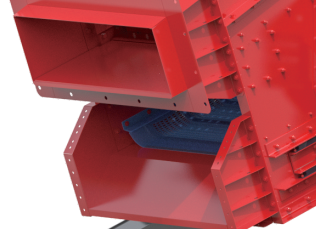

Composite Screen

The composite vibrating screen organically combines the two single screening technologies of the stepped circular vibrating screen and the relaxation screen into one, so that one device can achieve two screening effects at the same time.

Based on the principle of mechanical vibration, this equipment uses a single excitation source to provide excitation force and simultaneously drives the upper and lower sieve plates to produce different forms of vibration. The upper sieve plate is a circular vibration, and the lower sieve plate is a relaxation motion. The material moves in the screen machine Under the action of vibration projection, stratification, and transportation are realized, and materials smaller than the mesh size fall down and complete the particle size classification.

Product Parameter

|

Model

|

SZS-C1660

|

|

Power (KW)

|

45

|

|

Screening Area (mm)

|

1600*6000

|

|

Machine Dimension (mm)

|

7200*4000*6200

|

Machine Weight (KG) | 15T |

Capacity | 60-80m³/h |

Product Features

Double screening effect

The vibrating screen and the relaxation screen are organically combined into one, so that one piece of equipment can achieve two screening effects at the same time, greatly saving space for conveying equipment, steel structures, etc.

Modular design

It is convenient for maintenance and replacement and can be flexibly adjusted according to the production line. Different forms of screens can also be replaced according to material characteristics.

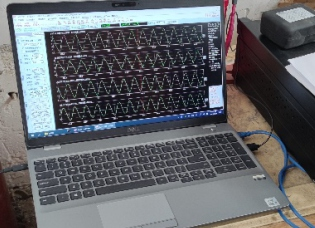

Performance optimization

Special instruments are used to detect and adjust various performance indicators before leaving the factory to ensure that the equipment reaches optimal operating status.

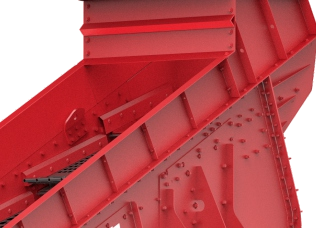

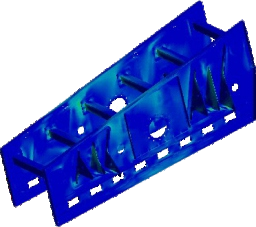

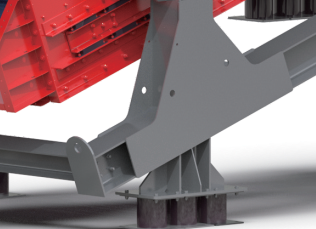

Structural optimization

The reinforced screen machine structure improves vibration fatigue life and overall reliability. The finite element method is used to make the structural design more reasonable, avoid resonance, and have better stability.

Diluted oil lubrication

The exciter bearing adopts double sealing and diluted oil lubrication, which effectively extends the bearing life and makes maintenance easier.

Convenient adjustment

According to material characteristics, vibration parameters can be quickly adjusted on-site

Secondary vibration isolation

Further reduce the vibration transmitted to the ground and reduces the impact on other equipment in the factory and production line

Smooth start and stop

Minimize start-stop jitter and reduce instantaneous impact on the screen machine and foundation. At the same time, the starting current of the motor is limited to reduce the power supply pressure of the factory.

Typical Application Range

Construction Waste

Waste Battery

MSW

Waste Plastic

Industrial Waste

Biomass Waste