Why did a cement company deploy more than a dozen RDF alternative fuel preparation projects?

- Share

- Issue Time

- Jan 25,2025

Summary

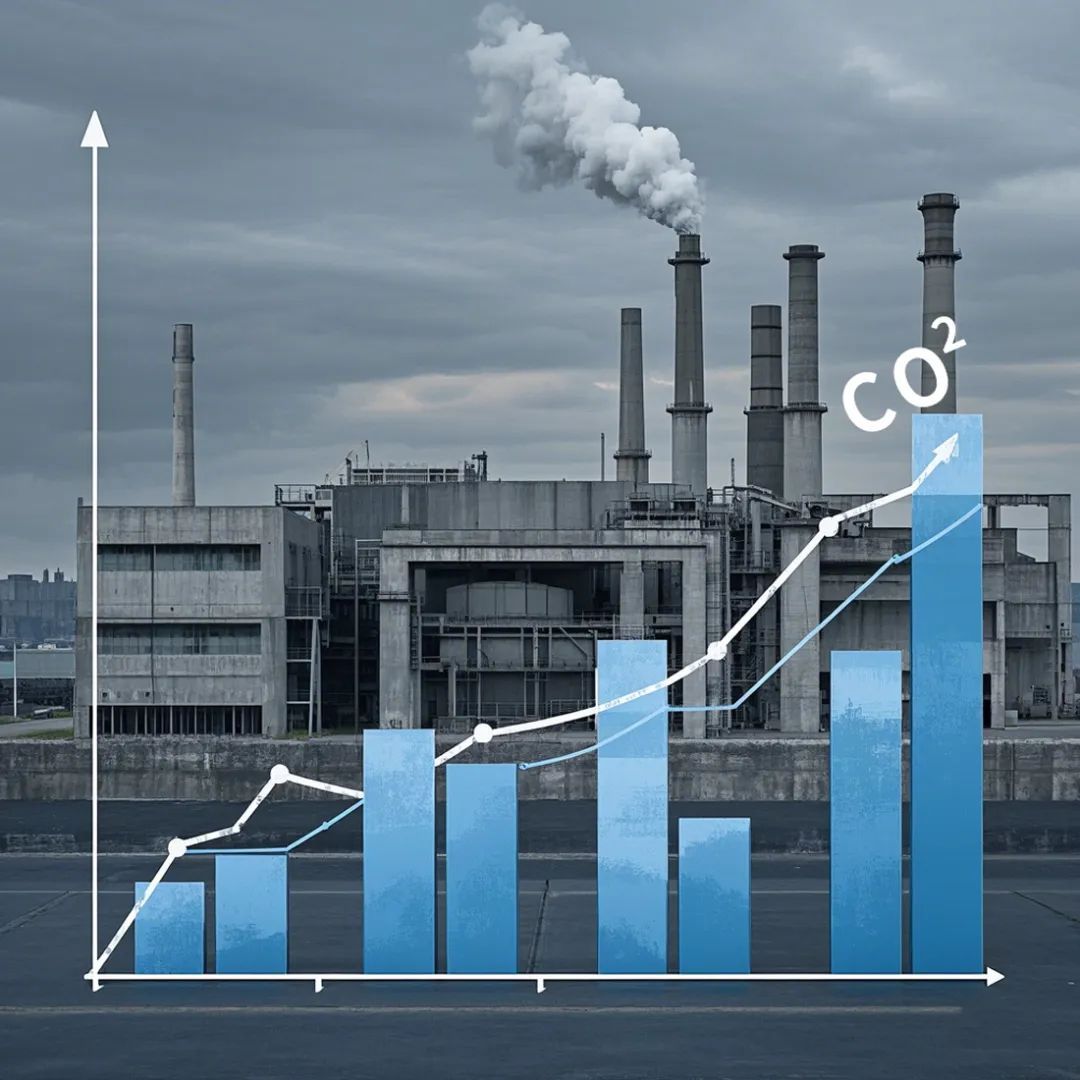

The cement industry is currently mired in multiple difficulties and is struggling.

On the one hand, as the popularity of infrastructure construction recedes and the real estate market continues to cool down, a large number of excess cement products are backlogged in warehouses.

Market competition has become increasingly fierce, prices have been continuously depressed, corporate profit margins have been severely squeezed, and survival pressure has increased sharply.

On the other hand, the cost of cement production is even worse. The price of raw materials has been rising, and energy costs such as coal and electricity have also remained high.

The total cost of cement production has been rising steadily. The company's already meager profits have been further eroded, and operating pressure has increased. heavy.

Coupled with the tightening of environmental protection policies, energy conservation and carbon reduction are like a more stringent hurdle.

Enterprises need to invest a lot of money in upgrading and upgrading environmental protection equipment to reduce emissions of harmful gases such as carbon dioxide, and actively explore green and low-carbon development paths.

This is undoubtedly a huge challenge for many cement companies that are strapped for funds and have difficulty in technological transformation.

While striving to meet environmental protection requirements, they must also take into account economic benefits. It is really a dilemma.

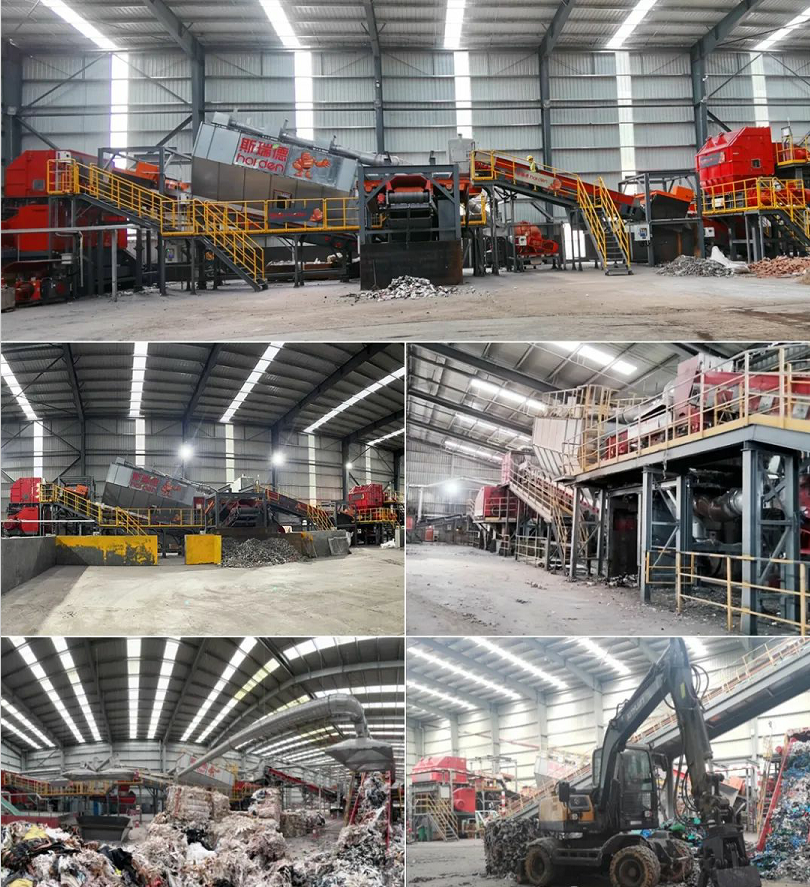

Faced with these difficulties, a domestic cement company conducted detailed market research and analysis and found a solution to the current predicament - RDF alternative fuel. It can replace fossil fuels such as coal and be used in cement kilns, thereby achieving the dual effects of reducing energy costs and reducing carbon emissions.

As a result, the cement company will start building RDF alternative fuel preparation centers in multiple regions in 2021. Up to now, there are more than a dozen RDF alternative fuel preparation projects completed or planned.

Harden Machinery’s RDF alternative fuel preparation system is suitable not only for a variety of solid waste materials, such as textile waste, industrial solid waste, biomass, bulky waste, decoration waste, etc.