Tackling Solid Waste Challenges: Environmental Advances of the Single-Shaft Shredder

- Share

- Issue Time

- Dec 6,2024

Summary

In the field of resource treatment, the single-shaft shredder is essential for effectively managing household, municipal solid, and biomass waste.

As global environmental issues gain prominence, the recovery and recycling of resources have become essential societal goals, underscoring the urgent need for effective industrial solid waste management. In multiple resource treatment sectors, such as household waste, municipal solid waste, and biomass waste, the single-shaft shredder emerges as a crucial tool for overcoming these obstacles.

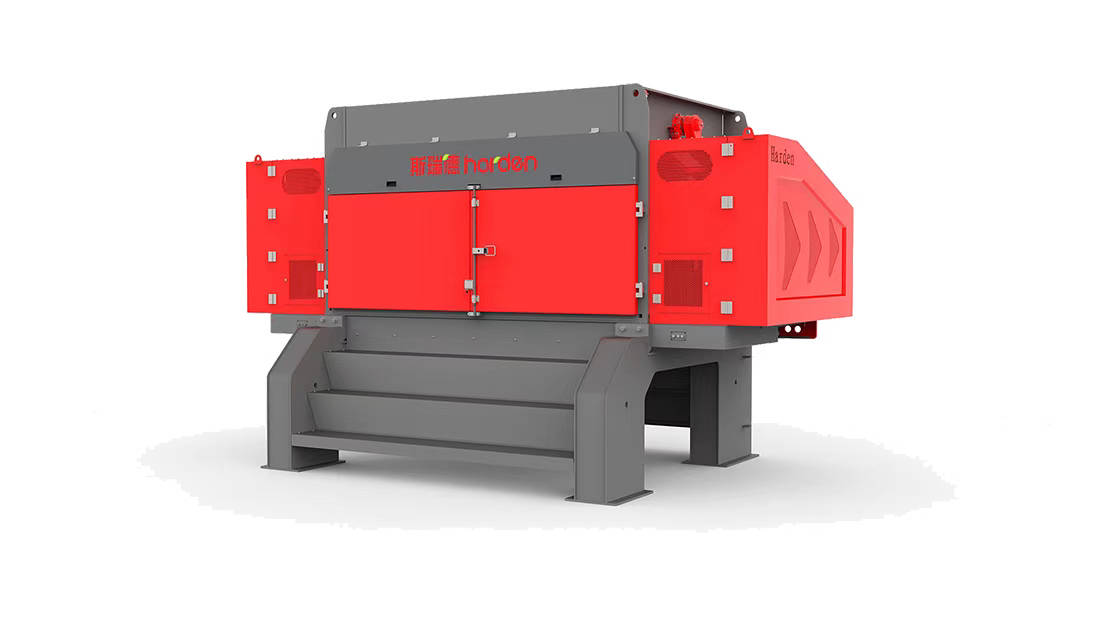

Single-Shaft Shredder: A Reliable Solution for Shredding Needs

Harden's single-shaft shredder showcases outstanding shredding capabilities due to its innovative design and sophisticated mechanics. It adeptly handles a diverse array of complex solid waste materials, irrespective of their shapes or compositions.

When dealing with rigid plastic waste, the machine utilizes tailored shear and compressive forces through its robust cutters and optimal speed settings, gradually breaking down the plastic into small, manageable pieces.

For straw, which is prone to tangling, the meticulously designed cutter configuration and operation efficiently avoid clogging, thereby boosting shredding efficiency.

Soft materials, such as waste paper and textiles, are reliably processed under the shredder's consistent power output and precise shredding mechanism, laying a solid foundation for subsequent recycling and safe disposal.

Leader in Precision for RDF Alternative Fuel Industry

Harden's single-shaft shredder is recognized for its precision in shredding, particularly in the preparation of RDF (Refuse-Derived Fuel) from waste materials—serving as a reliable pillar at the cutting edge of waste processing.

With its exceptional performance and efficient processing abilities, it brings significant advancements to the preparation of RDF alternative fuel. Due to the strict particle size requirements for shredding waste materials, accurate control and consistent shredding ensure that the material complies with RDF preparation standards, thereby greatly improving fuel quality and efficiency.

Stable Operation and Safety Assurance

Moreover, Harden's single-shaft shredder excels in operational stability. Its well-designed mechanical structure and high-quality components ensure stable, continuous operation over long durations, effectively lowering malfunction rates and providing solid support for continuous production.

Equipped with overload protection, foreign object detection, and safety interlock devices, these systems respond swiftly to anomalies, protecting equipment and operator safety.

Adaptability to Various Wastes: Responsive and Versatile

When facing materials of different characteristics, Harden's single-shaft shredder adapts its operational parameters flexibly to achieve optimal shredding outcomes. This adaptability allows it to handle complex and changing waste treatment scenarios with ease, further underscoring its significant role in industrial solid waste pre-treatment.

In summary, as a pioneering piece of equipment in the solid waste treatment domain, Harden's single-shaft shredder plays an indispensable role in advancing resource recovery, promoting harmless waste treatment, and providing strong support for efficient production across related industries.