High Resource Utilization! The practical application of vibrating screening equipment in solid waste!

- Share

- publisher

- Harden Machinery Ltd.

- Issue Time

- Jul 22,2024

Summary

How to comprehensively process solid waste such as MSW waste, decoration waste, and landfill mining into resources, harmlessness, and volume reduction has always been the core focus of environmental protection.

How to comprehensively process solid waste such as MSW waste, decoration waste, and landfill mining into resources, harmlessness, and volume reduction has always been the core focus of environmental protection.

Difficulties in screening from various types of solid waste

① Landfill mining is often left in the open air, soaked by rainwater, and has a very high wet viscosity, which can easily cause clogging of screening environmental protection equipment.

② Decoration waste is complex and diverse, with a high proportion of dirt, sand, and gravel. It is difficult for ordinary screening equipment to meet the market demand for high impurity removal rates.

③ The types of MSW waste are very complex and the wet viscosity is also high, making it difficult to achieve a resource utilization rate of more than 80%.

In response to the current situation where the sources of solid waste are becoming more and more complex and the terminal treatment requirements of the market are increasing, HARDEN has launched a new generation of vibrating screening equipment after years of independent research and development: flip-flow screen, ladder screen, and composite screen to help solid waste disposal resource management get to next level!

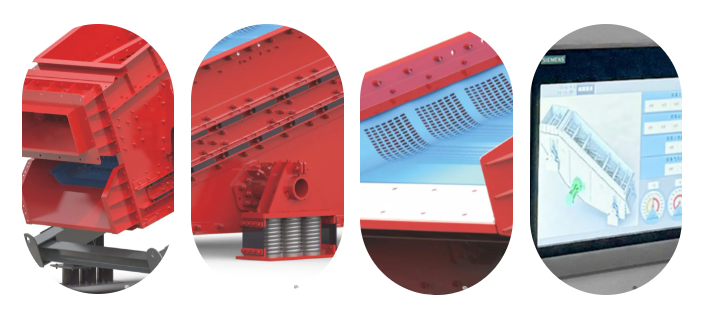

Flip-flow Screen

It consists of a fixed screen frame and a floating screen frame to form a vibration system, which produces relative motion at the same time.

In this process, the screen surface continuously stretches and contracts at a very high frequency, thus obtaining a large acceleration, which will cause the sticky while the wet materials are screened out, the clogging of the screen holes is effectively overcome.

It is good at handling solid waste with high wet viscosity and is not easy to block.

Ladder Screen

It adopts a stepped screen design. When the material falls from above, it can produce horizontal, vertical, and tilted three-dimensional movements.

Under the action of the vibrator, the material continues to jump and roll on the screen surface, which is smaller than the screen surface.

Materials smaller than mesh size continue to fall; materials larger than the mesh size are discharged from the screen surface, thereby achieving precise screening of materials of different sizes.

It is good at handling complex and diverse solid waste, achieving accurate screening effect.

Composite Screen

It combines the screening technology of flip-flow screens and ladder screens. It provides power through a single excitation source and drives the upper and lower sieve plates to produce different forms of motion.

The upper sieve plates are circular vibrations and the lower sieve plates are relaxation motions.

Materials are stratified and transported under the action of the vibrating projection of the screen machine and different screen meshes, thereby achieving the sorting of multi-level and multi-sized materials.

It is good at processing mixed solid waste with high wet viscosity, which is by the way of multi-level material sorting.

In response to the needs of practical applications in solid waste treatment, HARDEN’s vibrating screening equipment series has been updated and iterated many times and adopted a variety of new electrical automation technologies, such as: customized structural design, customized control system, and double isolation vibration technology, etc.

While meeting the demand for resource-based treatment of various types of solid waste, it also increases humanization.

① Modular structure design, convenient for maintenance and repair, and flexible replacement of different forms of screens.

② The intelligent control system can quickly adjust vibration parameters on site according to material characteristics.

③ Double isolation technology effectively reduces the impact of vibration on the factory building and other equipment in the production line.

It is said that solid waste is just a resource that has been misplaced. It is an urban mineral deposit with the greatest potential for development and will never be exhausted.

However, it is necessary to gradually achieve high resource utilization of solid waste and to use large-scale, refined and intelligent screens. Intelligent screening equipment is essential.

Challenge the high demand! High resource utilization! HARDEN solid waste screening equipment series - filp-flow screen, ladder screen and composite screen are here!