The Importance of Alternative Fuel Preparation for the Cement Industry

- Share

- publisher

- Harden Machinery Ltd.

- Issue Time

- Nov 4,2022

Summary

In the whole cement production process, the clinker production stage has the largest carbon dioxide emission, accounting for about 95% of the total production process, most of which comes from the calcination of limestone, a small amount from the fuel used in the process.

In

the whole cement production process, the clinker production stage has the

largest carbon dioxide emission, accounting for about 95% of the total

production process, most of which comes from the calcination of limestone, a

small amount from the fuel used in the process.

Moreover,

due to the increase in coal prices in recent years, the price has increased by

two to three times compared to the same period. Since this is the main fuel

used in cement production, it increases the production cost of enterprises to

some extent.

Therefore,

one of the most important things in carbon dioxide emission in the cement

industry is to reduce fossil fuel or even not use fossil fuel.

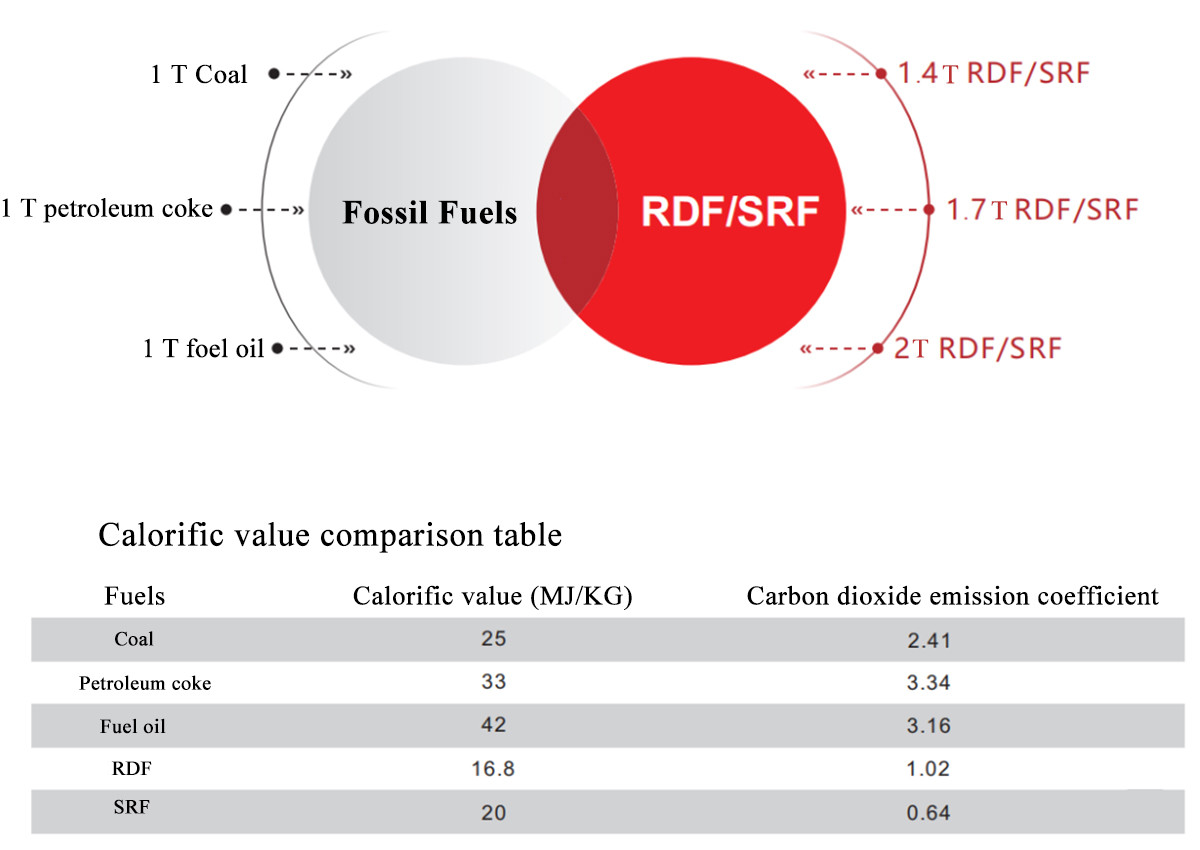

The Substitute Relationship Between SRF/RDF and Coal Fuel

The

solid recovered fuel (SRF)/refuse-derived fuel (RDF) preparation system

developed by Harden is based on the fuel perspective in the cement industry,

which extracts the high calorific value of combustible solid waste from the

waste, and then processes it to produce green energy. Not only the waste

reduction, harmless, resource, but also reduce the clinker production of fossil

energy consumption, so as to achieve carbon reduction and economic win-win.

As

one of the drafting units of the alternative fuel standard, Harden has been

deeply engaged in the solid waste treatment industry for more than ten years. We

have rich practical experience in the comprehensive reuse and treatment of

harmless, reductive and resource-based in municipal solid waste (MSW), general

industrial solid waste, bulky waste, paper mill waste, legacy waste, biomass

straw, waste rubber tires and other aspects.

Through

shredding, sorting, screening and granulation, Harden provides each industry

the reliable solid recovered fuel (SRF) Preparation system and equipment,

turning high calorific value solid waste into SRF/Refuse-derived fuel (RDF).

Under

the situation of carbon emission reduction, the implementation of green and

low-carbon circular economy recycles the combustible solid waste generated in

daily life and produces it into RDF/SRF, which can be used to replace coal,

oil, natural gas and other fossil fuels. It is an innovative development road

of energy conservation, emission reduction, green and low-carbon development in

the future of the world.