Some Suggestions on How to Choose a Suitable Shredder for Processing Solid Waste

- Share

- publisher

- Harden Machinery Ltd.

- Issue Time

- Nov 17,2020

Summary

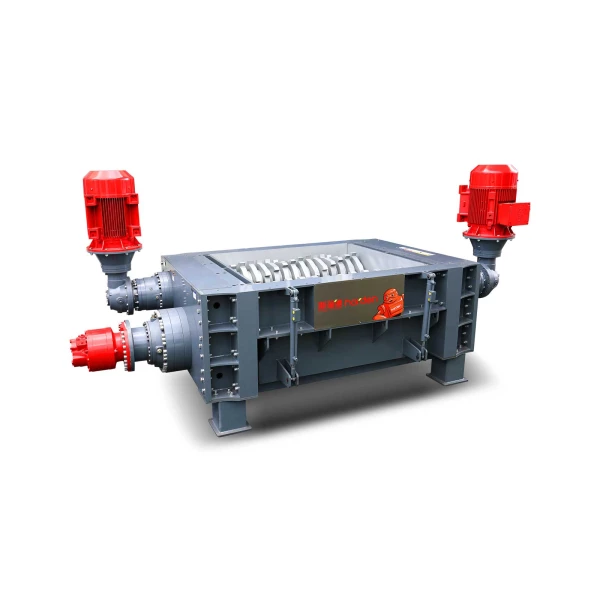

A good choice of solid waste shredder can help users solve problems. But how to choose a suitable one from a various types of shredders in the market is a skill. Now here we would like to give your some ideas from 2 aspects.

A good choice of

solid waste shredder can help users solve problems. But how to choose a suitable

one from a various types of shredders in the market is a skill. Now here we

would like to give your some ideas from 2 aspects.

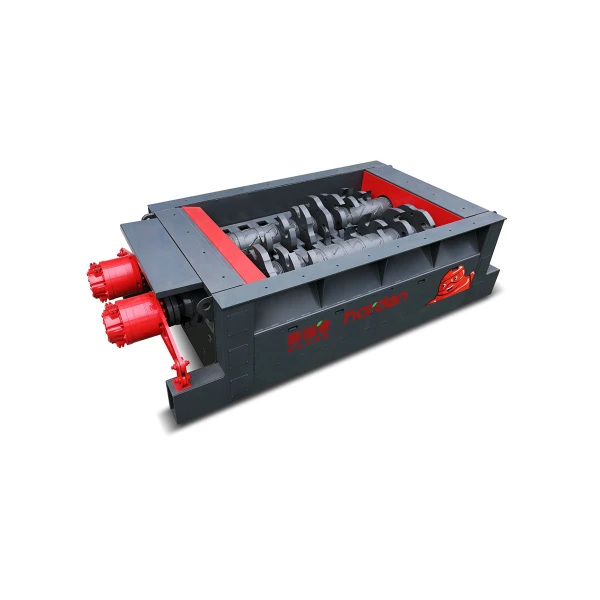

What size of solid

waste shredder we should choose?

Firstly, size

choice is based on the material characteristics and the requirement of discharge

size.

Secondly, we suggest

choosing a larger power shredder than the one that current crushing work

needed. Because as the operation time increases, the cutter will become blunt,

then more energy consumption is needed to shred the material. If the shredder

has sufficient surplus power, the shredder can continue operation for a longer

period of time without maintenance before tool replacement.

Besides, cutting chamber should be big enough, so the material should be grabbed as much as possible.

Finally, in addition

to the model and power, it is also necessary to consider factors such as the

size of the knife hook and distance between shafts, the feeding chamber, and the material

characteristics.

What kind of feeding method we should choose?

Batch feeding refers

to grabbing a large amount of material into the shredder hopper. Batch feeding

is generally used to deal with household garbage, hazardous waste, or bale

materials. However, the size of cutting chamber should be considered. If the size is

not appropriate, it will cause material blockage or affect crushing capacity.

Metered feeding

refers to feeding materials into the hopper at a stable control through a

conveyor. It is common to deal with bulky waste, light residue from paper mills

or fruits and vegetables, and kitchen waste.

If the material can

be metered and fed, the crusher can monitor its feed volume and adjust the

speed of the conveyed material. Then

feeding will be more effective, with fewer reversals or shutdowns.

Video