The Renovation Project of Changsha Hazardous Waste Disposal Center was Completed

- Share

- publisher

- Harden Machinery Ltd.

- Issue Time

- May 26,2022

Summary

The system is mainly aimed at the shredding treatment and incineration of tons of drums, 200L iron drums or plastic drums (empty drums or containing semi-solid, solid material sludge block, resin, paint residue, drugs, packaging bags, woven bags, waste cloth, and other bulk hazardous waste),and other materials.

The

system is mainly aimed at the shredding treatment and incineration of tons of

drums, 200L iron drums or plastic drums (empty drums or containing semi-solid,

solid material sludge block, resin, paint residue, drugs, packaging bags, woven

bags, waste cloth, and other bulk hazardous wastes) , and other materials.

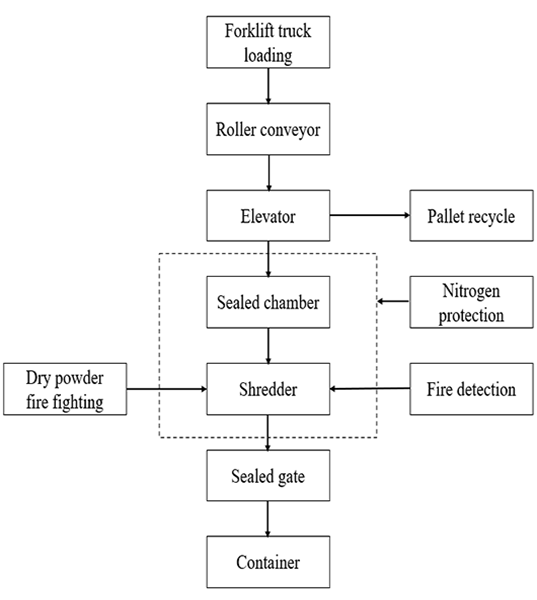

Process Flow of Changsha Hazardous Waste Disposal

Center

Changsha

hazardous waste disposal center has realized the intelligent automation of the

whole system. The material to be treated is first conveyed to the bottom cage

of the vertical elevator through the horizontal roller conveyor, and then

vertically lifted to the feeding height, finally sent into the sealed chamber

of the shredder through the export roller conveyor.

After

nitrogen is filled inside the sealed chamber, the material enters the shredding

area, the sealing gate at the bottom of the chute is opened after the shredding

treatment is completed, and the crushed material enters the container, which is

filled with material and then transferred to the pit, and at the same time, a

new cycle of "lifting - shredding" is started.

Five Advantages of Changsha Hazardous Waste Disposal Center

The

pretreatment of hazardous waste is the key link in the recycling of hazardous

waste. In the design of Changsha hazardous waste disposal center, Harden

developed hazardous waste pretreatment technology, and improved it according to

the project experience and domestic situation. Compared with the general

hazardous waste treatment system, Changsha project has the following

advantages:

1) Nitrogen

protection system & dry powder fire fighting system

Equipped

with nitrogen protection system, it can effectively avoid the combustion

situation in which the waste is fed into the shredding bin. The nitrogen analyzer monitors

internal nitrogen online, timely replaces nitrogen oxygen, to protect the whole

crushing process. In addition, the system is also equipped with dry powder fire

fighting system, flame detector detects shredding bin, discharge bin, and other

prone to fire space online. In case of fire, the system will automatically

alarm and start dry powder fighting device.

2) Modular structure design, easy installation

Adopts

modular structure design, the whole steel structure and parts are prefabricated

in the factory, greatly shorten the installation cycle.

3) Pallets can be recycled, cost saving

Using an advanced feeding system, one can choose different modes according to the actual situation. The pallet recycling design is convenient for loading and saves the cost of the pallet.

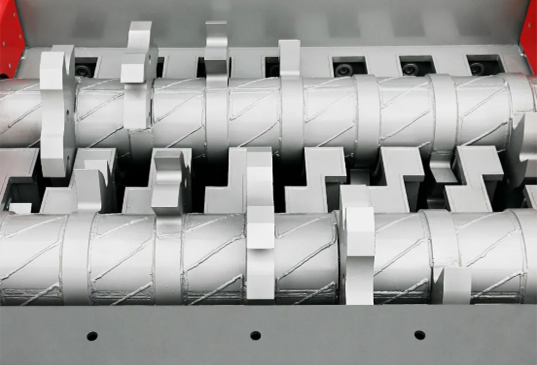

4) Primary shredder with excellent shredding performance

The large hydraulic driven coarse shredder shaft shredder from Harden reaches 0-40 r/min, with the mechanical characteristics of shredding, cutting, and extruding. After being broken, the size of the material is uniform, and the size is mostly controlled below 400mm. Barreled solidified materials and flexible material can be processed, which greatly reduces the amount of manual intervention to become more efficient and more adaptable.

5) Intelligent control system with high automation degree

The system adopts Siemens S7-1200 series, the elevator and shredder can synchronize automatic operation, through the detection of motor current and time control to judge the material situation in the shredding chamber. The whole system is highly automated, only 2 workers need to be configured on site, greatly saving labor costs.

The successful completion of the renovation project of Changsha hazardous waste disposal center has realized the safety prevention, control, and stable operation of hazardous waste from feeding to shredding, which demonstrates Harden’s professional ability and competitive advantage in solid waste shredding equipment and resource recycling one-stop solution. In the future, we will continue to focus on technology research and development, to provide our customers with more professional and efficient solid waste treatment one-stop service.